Oxygen Concentrator

- Tech Stack: Fusion360, Ansys, Autodesk CFD , Catia

- Summary

- Developed a hydrogen peroxide-based oxygen concentrator which was portable and safe to use as an alternative to existing products and making it eco-friendly with only water as the byproduct without using any electricity

- Ensured the concentrator was affordable and easily repairable by simplifying the design and the using the fluid properties of peroxide and using magnesium oxide plates as catalyst to control the output of oxygen

- In-Depth

Introduction

This project aims to create a portable device that can produce and supply clean oxygen to people who require it, such as mountaineers, scuba divers, and patients. The motivation for this project is to provide a more affordable and lightweight alternative to traditional oxygen cylinders, which are heavy and expensive. The objective is to use certain chemicals to react in the presence of a catalyst to produce clean oxygen and water, making it easier for mountaineers to breathe in rugged terrains.

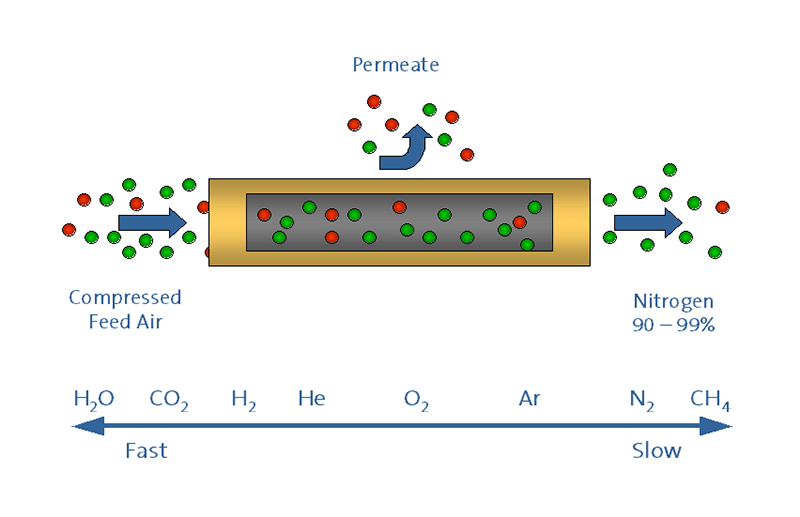

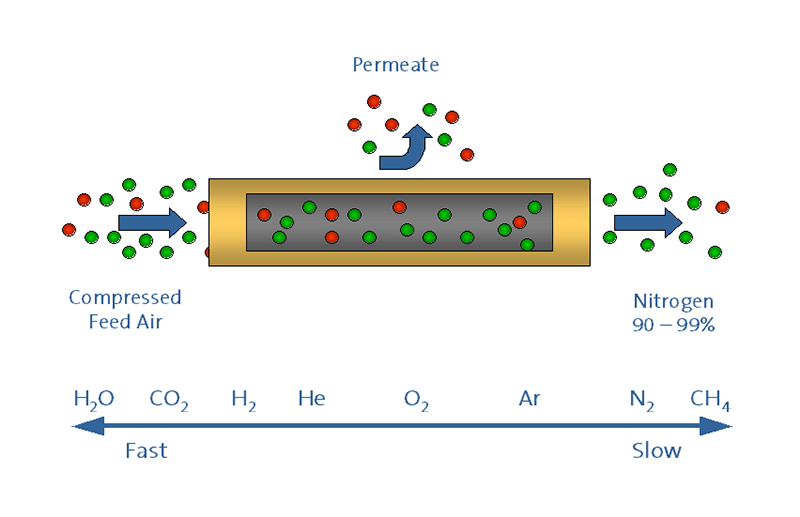

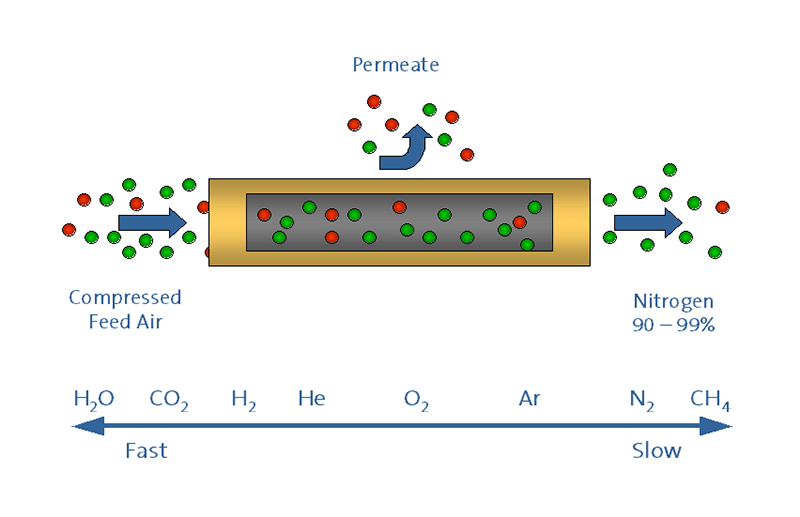

Currently in market there are two primary methods of producing oxygen: Pressure Swing Adsorption (Fig-1) and Membrane Gas Separation (Fig-2). Pressure Swing Adsorption and Membrane Gas Separation are two methods for producing concentrated oxygen. Pressure Swing Adsorption uses a process where air is compressed and passed through sieve beds containing Zeolite to absorb nitrogen, leaving oxygen-rich air. The process is cyclic with two sieve beds, and a cooling system and nasal cannula deliver the purified oxygen. In contrast, Membrane Gas Separation uses a non-porous polymeric membrane material to allow the rapid passage of oxygen molecules while minimizing the passage of others. Compressed air is directed down the center of the module fibers, where oxygen molecules pass through the wall of the fiber, and nitrogen molecules continue down the hollow fiber and exit at the opposite end.

Fig-1 Pressure Swing Adsorption Workflow

Fig-2 Membrane Gas Separation Working Motivation

The motivation behind this project is to provide a cost-effective and lightweight alternative to oxygen cylinders for mountaineers. Currently, mountaineers have to carry heavy oxygen cylinders with them on their journey, which can be a major inconvenience and financial burden. Our goal is to make it easier for mountaineers to breathe in high-altitude environments, so they can enjoy the terrain without being weighed down.

Fig-3 Isotropic view of the CAD-design Objective

The objective of this project is to create a device that uses chemical reactions to produce clean oxygen and water, making it a more sustainable option compared to traditional oxygen cylinders. The device should be portable, lightweight, and affordable, so that it can be easily carried by mountaineers during their journey. By using this device, mountaineers will no longer have to rely on heavy oxygen cylinders and can instead breathe in clean oxygen, which will help them acclimate to high-altitude environments more easily. Ultimately, our goal is to create a safer and more enjoyable experience for mountaineers.

Fig-4 Top and Bottom View of the CAD-Design Conclusion

In conclusion, the research paper presents a new product that uses the reaction of H2O2 with MnO2 to produce oxygen and water. This method is cheaper and lighter than current oxygen concentrators and tanks, making it an ideal solution for various applications such as scuba diving, mountaineering, and medical purposes. Additionally, 3D printing using durable polycrystalline material could potentially reduce manufacturing time and improve the product's quality. The weight reduction of more than 5kg compared to current products is significant and has the potential to decrease even further with advancements in 3D printing technology. The estimated cost reduction from Rs. 75000 to Rs. 12000 is a major benefit for users who require supplementary oxygen. Overall, this new product has great potential to improve the quality of life for individuals in need of oxygen supplementation while also reducing costs and improving convenience.